Pile breaking with brains is now also available in Austria.

TEXT: SONJA MESSNER

Labor-intensive and therefore cost-intensive, unecological and imprecise – even if pile breaking only accounts for a small part

of specialist foundation engineering work, it can still make a significant contribution to the success or failure of a project. Currently, bored piles are mainly driven with air or hydraulic hammers and thus with vertical impact energy. As this processing energy is difficult to control, there is a risk of cracks in the concrete body and spalling on the outer skin of the pile. This can cause corrosion damage. In addition, the last 30 to 50 centimeters have to be painstakingly cut away by hand.

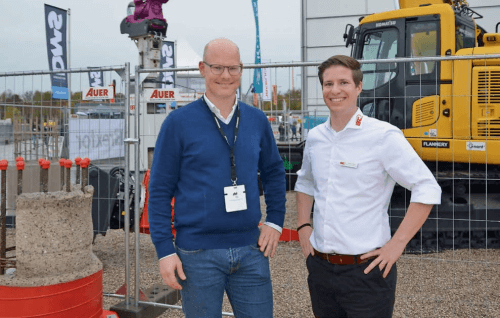

Dominik Horacek, Technical Manager Construction at the Austrian earthworks company Gnant, has long been concerned about the inefficiency of pile breaking. “The reliability of the contractors is always an issue, which can quickly lead to significant construction delays,” explains Dominik Horacek. “And the physical strain is also insane.” By chance, they came across the solution from the Swiss company BRC Engineering, and within a very short time the co-operation was agreed.

The Brextor principle

The Swiss company has been developing the Brextor pile head milling machine (pile breaking machine) including concrete biter for over ten years. With different milling head sizes, which can also be individually adapted, the Brextor system can process pile heads of less than half a meter to two meters. The horizontal application of force should enable 100 percent control of the processing energy used. With a height accuracy of plus/minus one centimeter, the pile head can be handed over to the next stage of work. “We can’t avoid manual work completely, but we can reduce it to a minimum,” explains Roland Pfister, Head of Sales International at Brextor. The time saved by the new method is impressive: With a pile head 100 centimetres in diameter and 100 centimetres high, the Brextor pile breaking machine only takes one hour, says Pfister.

1. Prepare pile with milling disk. 2. Milling down to level (+/– 1 cm height accuracy). 3. Breaking out the remaining concrete with the BRC pile head crusher. 4. Cleaning and aligning the reinforcement.

But only faster and more accurate is not enough if the costs are not right. “Of course, using Brextor is not cheap – but calculated over the entire project cycle, our system is more economical in most cases,” emphasizes Pfister. One of the reasons for this is that the milling head converts most of the excavated material directly into gravel with a grain size of 0 to 30 millimeters, allowing it to be processed directly on the construction site as backfill. Less excavation work is also required around the pile head. “This has a positive effect on costs and the CO2 footprint,” says Pfister.

Great potential in Austria

“Our machine operators have already been trained in Switzerland. We are now offering the solution exclusively in Austria. This is a significant step in the direction of offering the excavation pit as a turnkey solution,” reports Dominik Horacek from Gnant. The long-term plan is to set up a competence center for training and application at the Gnant site.

Great potential is seen in Austria. The technical manager is convinced that up to six Brextor devices could be used in Vienna and the surrounding area alone.

Original press release in German.